What is Cycle Count?

A Smarter Way to Manage Inventory

Cycle counting is a modern, continuous approach to inventory management that eliminates the need for full physical inventory shutdowns. Instead of counting every item in the warehouse at once, businesses count small groups of items regularly throughout the year. This helps maintain inventory accuracy without disrupting operations.

Benefits of Cycle Counting Inventory

Cycle counting offers several operational advantages. It reduces warehouse downtime by spreading inventory checks across different time periods. It enhances accuracy, minimizes costly fulfillment mistakes, and helps companies stay audit-ready with ongoing records validation. Most importantly, it reduces stress by preventing last-minute inventory scrambles.

Continuous Accuracy

Stay ahead of errors by verifying stock levels frequently.

Reduced Downtime

No need to pause operations for full physical counts.

Improved Forecasting

Real-time inventory accuracy leads to better purchasing and fulfillment decisions.

Fewer Stockouts and Oversells

Early detection of discrepancies helps keep inventory balanced.

How Does Cycle Counting Work?

During a cycle count, specific items are selected based on criteria such as location, value, or frequency of movement. Staff members then physically count these items and compare the results to inventory records in the system. If discrepancies are found, they can be investigated and corrected immediately—keeping your data clean and actionable.

01

Define Strategy and Criteria

-

Choose your method: by value, location, or movement frequency

-

Set up a recurring cycle count schedule

-

Assign responsible team members

02

Select and Prepare Items

-

SKULabs selects items based on your criteria

-

Notify your warehouse team of upcoming counts

-

Ensure access to the relevant storage areas

03

Compare and Adjust

-

SKULabs compares physical count to recorded inventory

-

Discrepancies are adjusted automatically or manually

-

Root causes of discrepancies are documented

04

Analyze and Optimize

-

Review reports generated from the cycle count

-

Identify recurring issues or high-error areas

-

Update strategies and provide staff training if needed

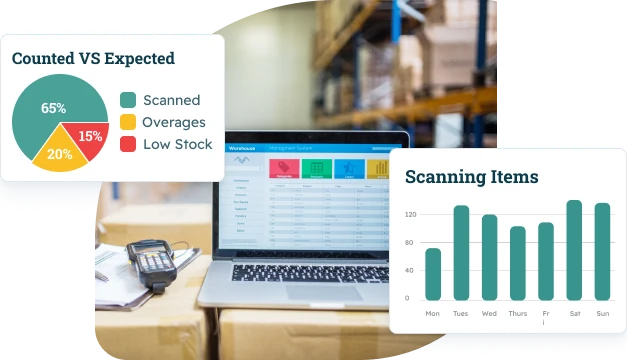

Cycle Counting With SKULabs

With SKULabs, cycle counting becomes a fully integrated, streamlined process. Assign counts to team members, scan items with mobile devices, track every action with audit logs, and reconcile inventory in real-time. SKULabs supports scheduled counts, tag-based filtering, and automated stock adjustments for maximum efficiency.

Why Cycle Count Inventory Matters

Cycle counting is not just a time-saver—it’s a competitive advantage. Companies that prioritize consistent, high-accuracy inventory can reduce shrinkage, optimize purchasing decisions, and deliver better customer experiences. By embracing cycle counting, businesses gain the confidence to scale operations without compromising control.

Cycle counts, sometimes called stock takes, are small batches of inventory counting tasks for a single location, or a single group of items, within a warehouse. Performing cycle counts frequently for smaller portions of your inventory allows you to keep stock levels accurate without interrupting your day-to-day operations.

Customer support like you’ve never experienced before

United State Based

Never outsourced, our support team operates 100% in-house from our South Florida offices

Quick Response Time

Most emails and tickets are answered within 4 hours, and our phone support team is available 7 days a week.

Tickets and Phone

Contact us via our support ticket system or our toll-free phone line. Call us +1 (800) 243-2986