It’s not enough to place regularly scheduled purchase orders, either. You can be caught without stock even when you have goods on order, simply because you didn’t order at the right time. All it takes is one spike in sales demand or one delay in receiving new inventory to put you at risk of running out of stock.

To address these risks, it’s important to plan ahead when building an inventory reordering strategy. Using a combination of previous sales history, trends in sales and demand, and the average lead time to receiving new inventory, you can set a reliable reorder point for each of your products. This practice is called inventory forecasting.

Measure sales trends

Many ecommerce businesses place orders with suppliers on a certain date, or when their stock reaches a certain level. However, a simple, static reorder point won’t help you if your sales fluctuate over time. Sales trends are the biggest factor in determining how much of a product you need to reorder and when.

To calculate your ideal reorder point for a product, look back to historical sales data. Figure out the average daily quantity that you expect to sell of that product in the near future. Use as much historical data as possible, but pay close attention to sales periods with similar trends as you’re currently dealing with. An upcoming seasonal change or holiday event can drastically change sales demand, so take those dates into account.

Calculate lead time

Unless your business is served by a supernatural supplier, you probably have to order many days or weeks in advance of when you expect to receive new inventory. This lead time is a huge factor in your inventory forecasting needs, and must be taken into account when determining when you need to place an order.

Look at past purchase order invoicing and receipts to see how long each supplier takes on average to get goods to your door. Make sure to account for any extra processing time, such as before your supplier ships the goods, or before you process those goods for sale.

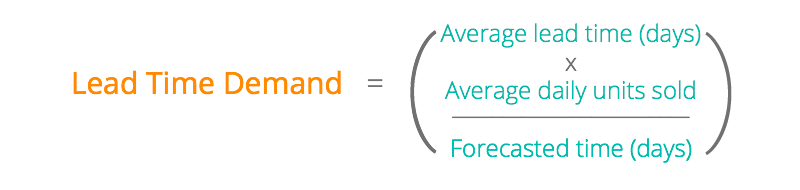

Adjust for lead time demand

At this point, you should have a solid estimate of how much of a product you expect to sell in the near future, as well as how long it will likely take to receive more of that product. However, simply gauging how long it will take to receive the goods is not enough. You may need to increase your purchase amount to accommodate for the projected demand during that lead time.

Look at the average number of sales per day for each of the products you’re restocking. Ideally, you can use data from a similarly trending time period to calculate this average. Multiply that daily average by your lead time to see your lead time demand. This figure will need to be accounted for in your purchase amount, in addition to the forecasted sales after you receive the new inventory.

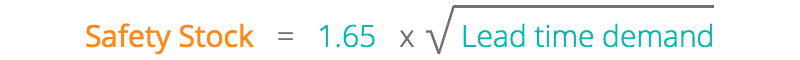

Calculate safety stock

Your store probably doesn’t get the exact same number of orders for the exact same products every day. Supply and demand is more organic than simple math can keep up with, and fluctuations are bound to happen. That’s why it’s important to give yourself a buffer when ordering inventory. You want extra stock to help prevent overselling during a spike in demand or a delay in receiving new inventory.

This “buffer” is called safety stock. Safety stock is an extra layer of inventory kept in reserve to make sure you don’t run out of stock of your key products. The amount of safety stock you choose to keep on hand can affect your operating costs and your likelihood of overselling, and ultimately the amount you choose to keep is up to you. There are some complex formulas out there in use by logisticians, but here’s a simple equation that can cover most retail scenarios:

This formula assumes a 95% confidence rate in the forecasted demand and lead time, as well as a normal distribution of lead time demand. These assumptions mean that the formula will always overestimate the safety stock needed by varying amounts. Naturally, it’s better to have slightly too much stock on hand than not enough to cover demand, so tweak your own numbers carefully.

Set reorder points

Reordering inventory is a balancing act. If you don’t have enough stock on hand to cover your reorder lead time, you’re already reordering too late. If you place an order and end up with a ton of extra stock taking up shelf space, you reordered too early. Fortunately, there are steps you can take to calculate that reorder point sweet spot.

![]()

Use your lead time demand and some additional safety stock to set a stock level to reorder upon reaching. Once you reach this low inventory level, you’ll have enough stock to cover your projected demand during the time it takes to receive the new stock. You’ll also have an added buffer to protect against a spike in demand or a delay in delivery.

If this sounds like a lot of work to figure out and keep track of, don’t worry! Modern inventory management software can help you calculate and set the right reorder points with built-in forecasting and reordering tools. They can even help you create and send purchase orders in the same package.